New chip-sized device could help manufacturers measure laser power in real time

Lasers play roles in many manufacturing processes, from welding car parts to crafting engine components with 3D printers. To control these tasks, manufacturers must ensure that their lasers fire at the correct power.

But to date, there has been no way to precisely measure laser power during the manufacturing process in real time, while lasers are cutting or melting objects, for example. Without this information, some manufacturers may have to spend more time and money assessing whether their parts meet manufacturing specifications after production.

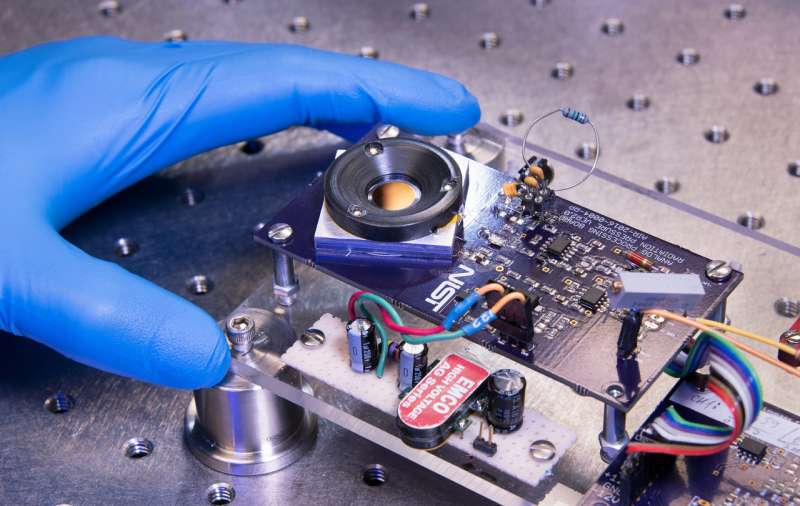

To address this need, researchers from the National Institute of Standards and Technology (NIST) have been developing a laser power sensor that could be built into manufacturing devices for real-time measurements. They present the results from their latest prototype in an October 2018 issue of IEEE Sensors.

The new device works in a similar way to a previous sensor made by the team, which uses radiation pressure, or the force that light exerts on an object. But unlike their older device—a shoebox-sized "Radiation Pressure Power Meter (RPPM) for ultrahigh-power lasers of thousands of watts—the chip-sized "smart mirror" is designed for lasers of hundreds of watts, the range typically used for manufacturing processes.

"It's still a radiation-pressure power meter, but it's much smaller and much faster," with 250 times the measurement speed of their larger sensor, said NIST's John Lehman. The smart mirror is also about 40 times more sensitive than the RPPM.

The kinds of manufacturing processes that could potentially use this new technology include everything from airplanes and automobiles to cellphones and medical devices. The smart mirror could also be integrated into machines employed in additive manufacturing, a type of 3D printing that builds an object layer by layer, often using a laser to melt the materials that form the object.

Someday, the researchers say, these tiny meters could be in every additive manufacturing machine and in every laser weld head.

"This would put the high accuracy of NIST power measurements directly in the hands of operators, providing standardized quality assurance across laser-based systems and helping to accelerate the process of part qualification," which ensures that manufactured objects meet engineering specifications, said NIST's Alexandra B. Artusio-Glimpse.

Conventional techniques for gauging laser power require an apparatus that absorbs all the energy from the beam as heat. Measuring the temperature change allows researchers to calculate the laser's power.

The trouble with this traditional method is that if the measurement requires absorbing all the energy from the laser beam, then manufacturers can't measure the beam while it's actually being used for something.

Radiation pressure solves this problem. Light has no mass, but it does have momentum, which allows it to produce a force when it strikes an object. A 1-kilowatt (kW) laser beam has a small but noticeable force—about the weight of a grain of sand.

By shining a laser beam on a reflective surface, and then measuring how much the surface moves in response to light's pressure, researchers can both measure the laser's force (and, therefore, its power) and also use the light that bounces off the surface directly for manufacturing work.

International Conference on Welding Technology

Visit Our Website:http://welding.sciencefather.com

More Details:

Abstract Submission - https://x-i.me/wtcvish1

Award Nomination - https://x-i.me/wtavish2

Blogger:https://weldingtechnologyawards.blogspot.com

Comments

Post a Comment