GE installs world's first spiral-welded wind turbine tower

The strongest winds tend to be higher up, but as this 2022 study shows, higher-mounted turbines catching stronger wind doesn't necessarily equate to the lowest cost of energy. Indeed, once you factor in the costs of stronger foundations and taller, sturdier towers, anything above about 120 m (394 ft) tends to result in more expensive electricity – and in a market as price-sensitive as energy, that's bad news.

Somewhere around half the Levelized Cost of Energy (LCoE) in an average commercial wind energy installation comes directly from the cost of the wind turbines themselves, according to the NREL. Of that, nearly half of the money's in the nacelle at the top, and the remainder is split between the rotors, which contribute around 13.7% to the LCoE, and the tower itself, at around 10.3%.

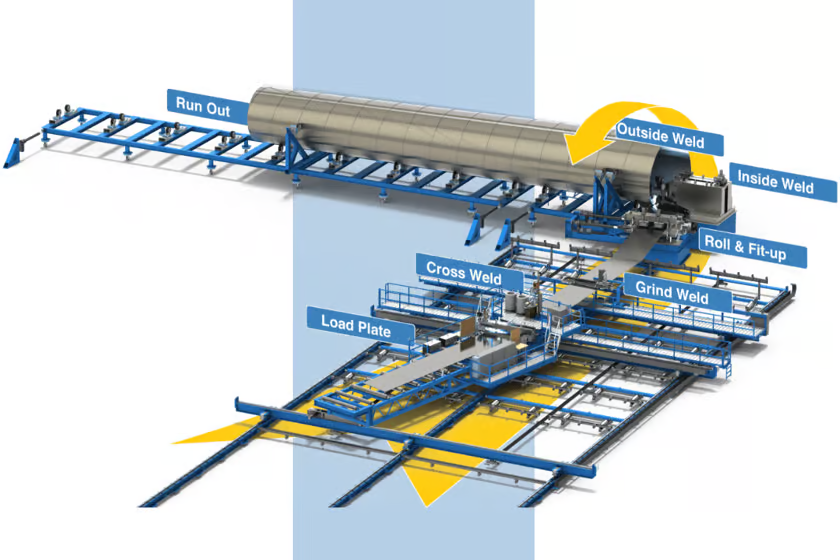

The idea is simple enough; instead of creating a number of cylindrical "cans," trucking them to the turbine site and welding them together to create the final tower structure, Keystone proposes rapidly building small manufacturing facilities on-site, then trucking in coils of steel in bulk, or even flat sheets, which can be welded together to form longer strips.

These coils or strips are fed into angled bending machines that bend them into a spiral shape, which is welded together along the join line continuously as the steel is turned. Much of the process is automated, as you can see in the video below.

Pinterest: https://in.pinterest.com/

Comments

Post a Comment